Export News

Export News

21-07-2023

21-07-2023

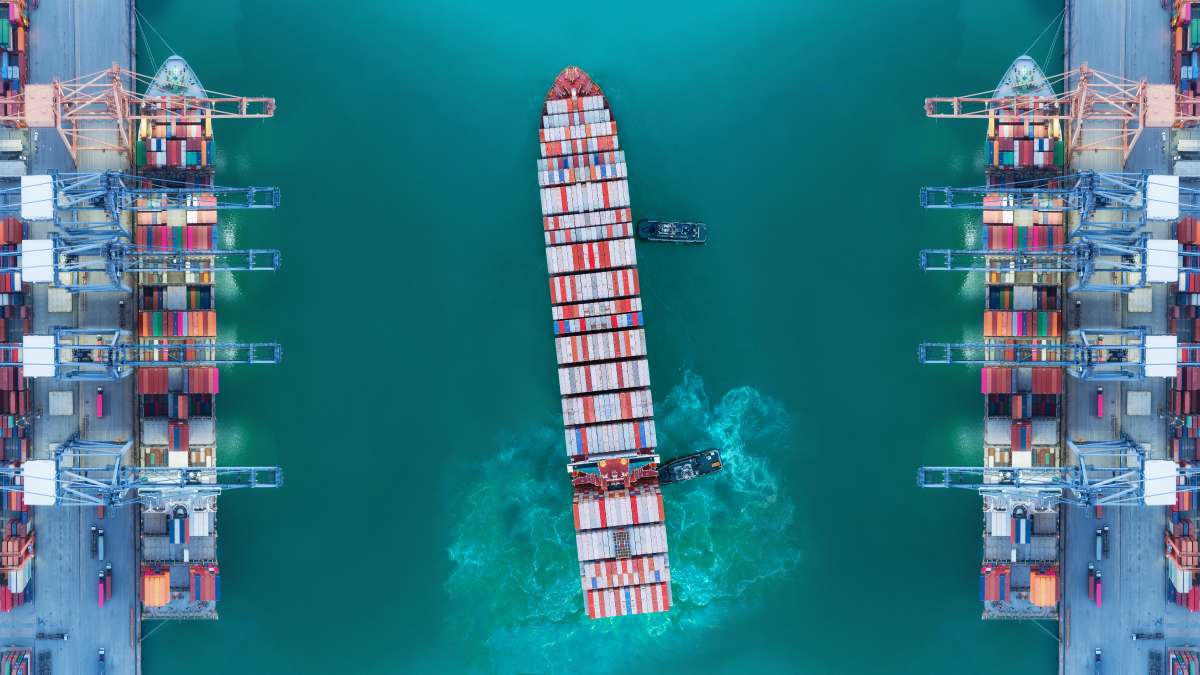

The export of dye jiggers is an essential aspect of the global textile industry. Jiggers export, also known as dyeing machines or dye jigs, are specialized equipment used in the dyeing process of fabrics and textiles. In this article, Tendata will explore the main export types of dye jiggers and their significance in the international trade of textile machinery.

Overview of Dye Jiggers and Their Importance:

Dye jiggers are widely used in textile dyeing operations to impart color to fabrics and fibers. They play a crucial role in the textile manufacturing process, enabling efficient and uniform dyeing of various materials. As the demand for dyed textiles continues to grow worldwide, the export of jiggers is essential and has become a vital component of the textile machinery trade.

Conventional Dye Jiggers:

Conventional dye jiggers are one of the primary export types of dye jiggers. These machines feature a large vat, where the fabrics are dyed in a continuous loop. The fabric is guided through the dye liquor by rollers, ensuring even dye distribution. Conventional dye jiggers are well-established and widely used in the textile industry, making them a popular export choice.

High-Temperature Dye Jiggers:

High-temperature dye jiggers are specialized machines designed to handle dyeing processes at elevated temperatures. They are equipped with advanced heating and cooling systems to accommodate dyeing at high temperatures for specific types of fabrics, such as polyester and nylon. These machines offer precise temperature control, making them ideal for certain dyeing applications and contributing to their prominence in exports.

Overflow Dye Jiggers:

Overflow dye jiggers are another significant export type of dyeing machines. These machines utilize an overflow system to ensure even and consistent dyeing of fabrics. The excess dye liquor is continually removed from the dye vat and recirculated, allowing for efficient and uniform dyeing. Overflow dye jiggers are known for their excellent dye penetration and high dyeing productivity.

Eco-Friendly Dye Jiggers:

In recent years, there has been a growing demand for eco-friendly textile machinery, including dye jiggers. Eco-friendly dye jiggers use innovative dyeing processes that reduce water consumption, energy usage, and chemical waste. These machines are designed to promote sustainable dyeing practices in the textile industry, making them an increasingly sought-after export type.

Digital Dye Jiggers:

With advancements in technology, digital dye jiggers have emerged as a new export type in the market. These machines use digital control systems to precisely manage the dyeing process, allowing for greater flexibility, reproducibility, and customization. Digital dye jiggers offer enhanced automation and ease of operation, catering to the evolving needs of textile manufacturers.

Conclusion:

The jiggers export plays a vital role in supporting the global textile industry's dyeing operations. Conventional dye jiggers, high-temperature dye jiggers, overflow dye jiggers, eco-friendly dye jiggers, and digital dye jiggers are among the main export types. Each type offers distinct advantages and features to cater to the diverse requirements of textile manufacturers worldwide. As the textile industry continues to grow and innovate, the demand for various types of dye jiggers is expected to remain strong, driving the export trade and contributing to the advancement of textile dyeing practices.

Category

Leave Message for Demo Request or Questions

T-info

T-info T-discovery

T-discovery

My

Tendata

My

Tendata Market Analysis

Market Analysis Customer

Development

Customer

Development Competitor

Monitoring

Competitor

Monitoring Customer Relationship

Customer Relationship